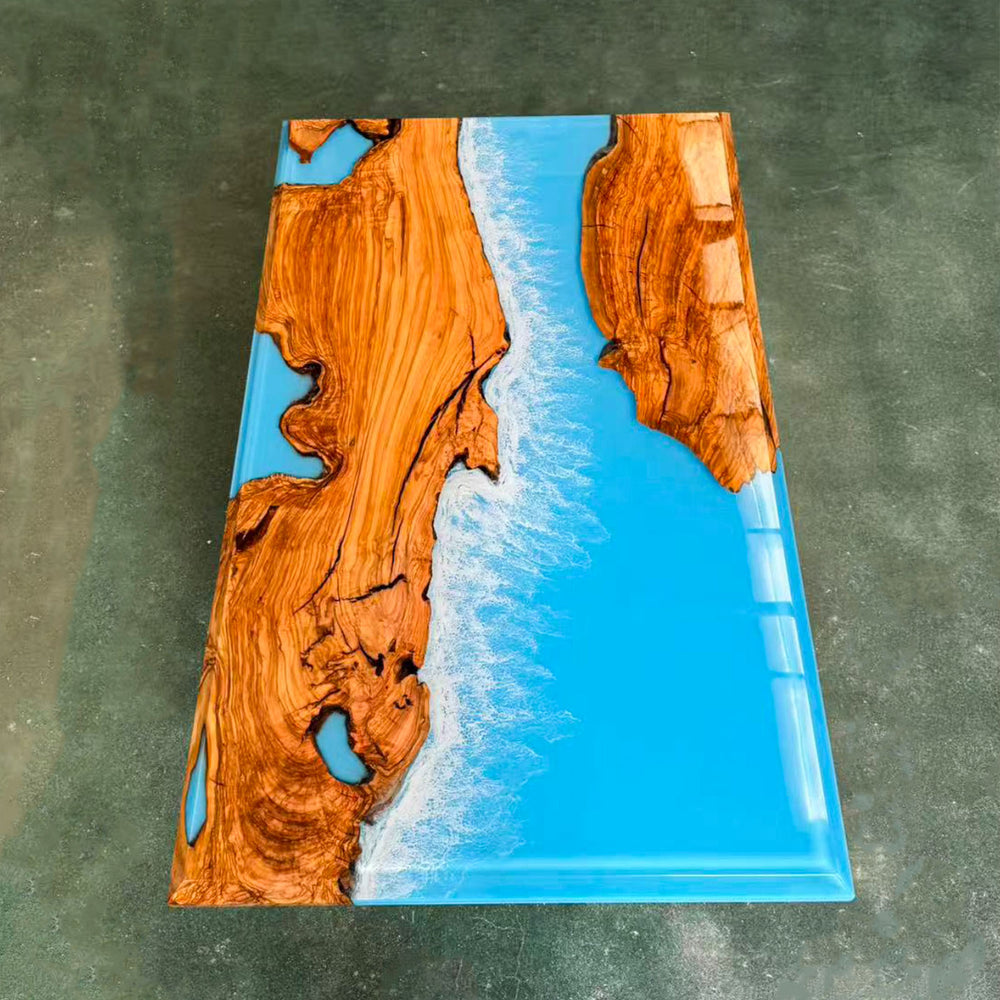

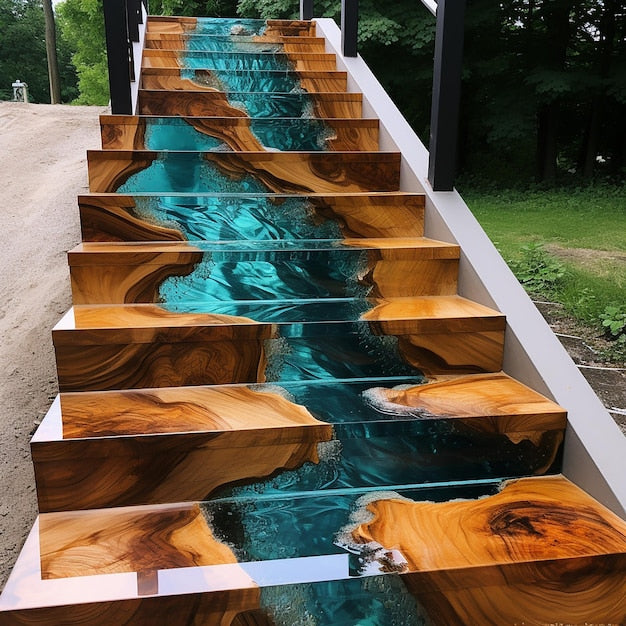

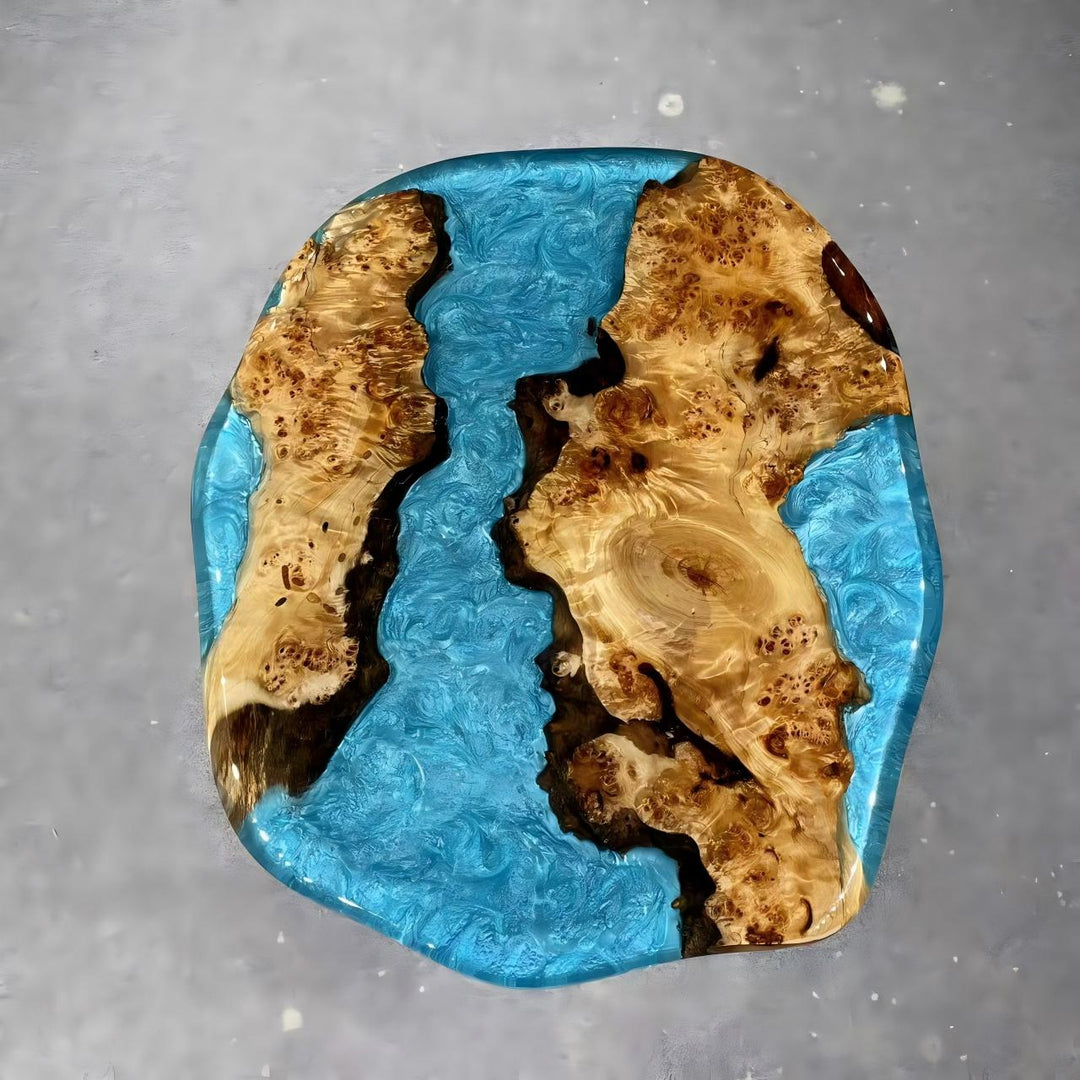

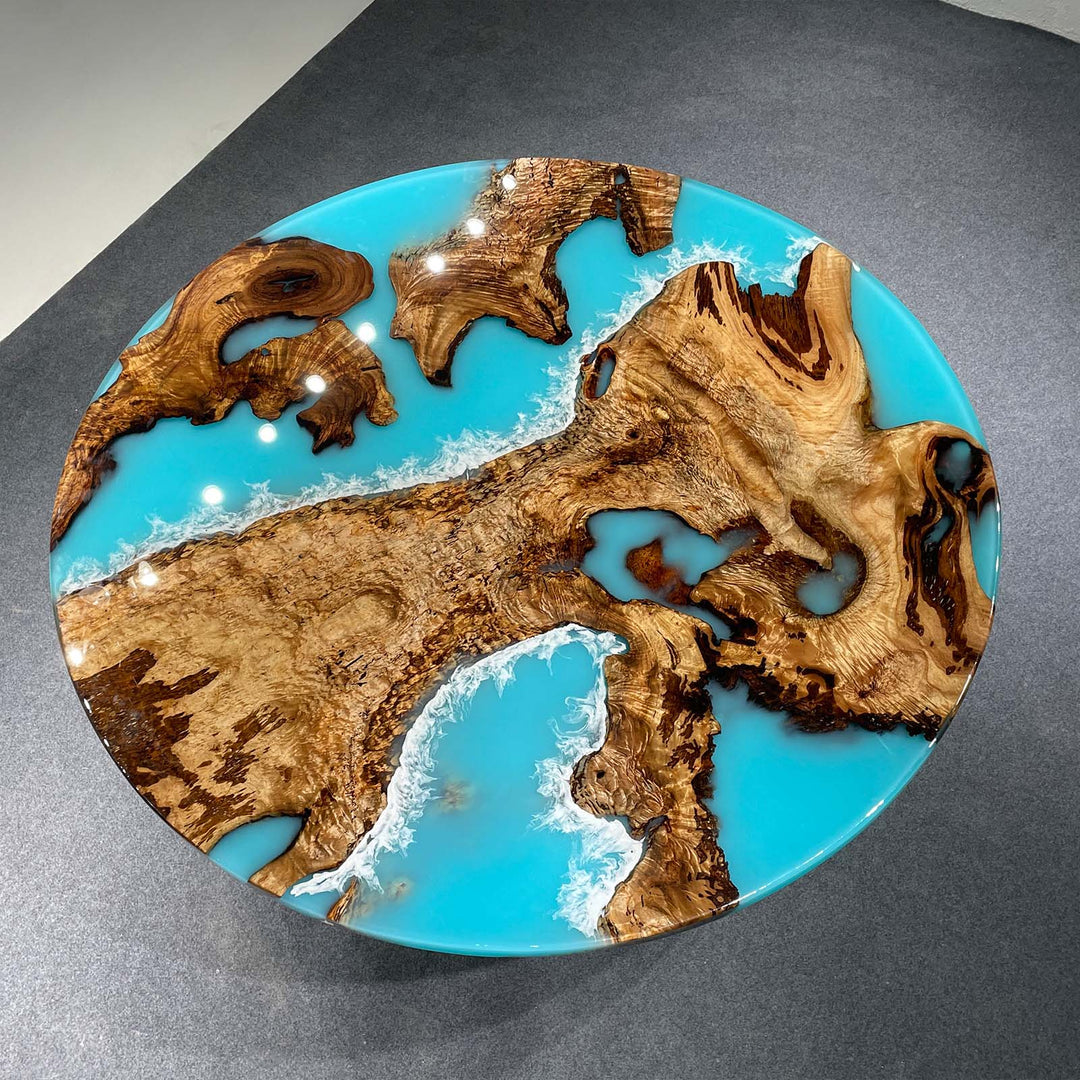

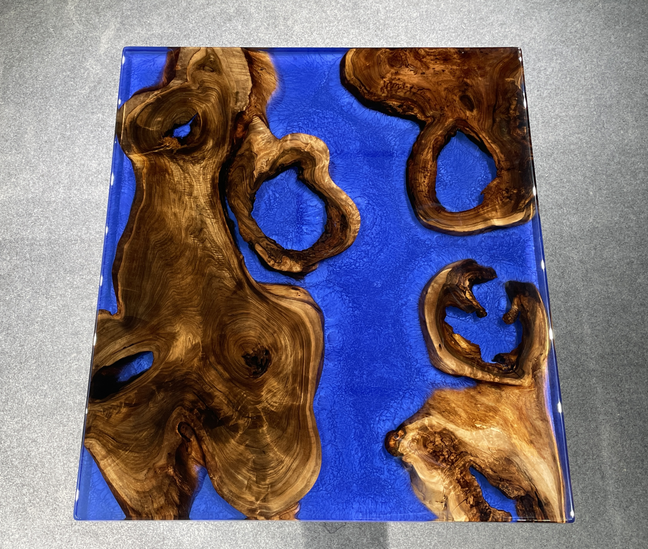

Custom Epoxy River Dining Table

Discover artisan-crafted epoxy tables that blend functionality with natural beauty. From elegant live edge dining tables to stylish wooden coffee tables and custom epoxy countertops, each piece is uniquely designed to elevate your space with character and craftsmanship.