Custom Epoxy Resin Live Edge Ice Crystal Dining Table CRT-036

Custom Epoxy Resin Live Edge Ice Crystal Dining Table CRT-036

-

-

Elevate your dining space with the Custom Epoxy Resin Live Edge Ice Crystal Dining Table CRT-036. This table perfectly marries the natural allure of live edge wood with the sleek elegance of epoxy resin, creating a stunning centerpiece for any dining area.

Features:

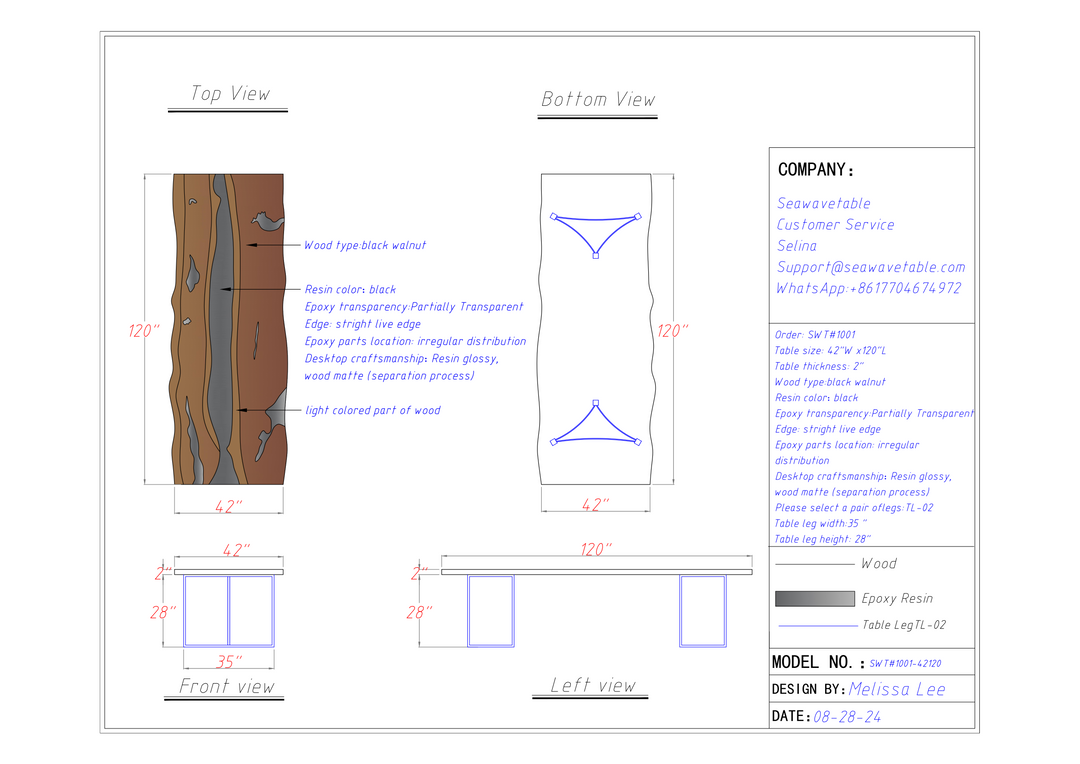

- Premium Wood Selection: Choose from Black Walnut, Walnut, Poplar, Cunninghamia, Ash Wood, Olive Wood, or other customizable wood types to match your aesthetic preferences.

- Unique Edge Options: Available in live edge, straight live edge, and straight cut edge to showcase the wood’s natural texture or provide a contemporary, streamlined look.

- Custom Resin Placement: The epoxy resin can be positioned in the middle, on the sides, or fully customized according to your design vision.

- Ice Crystal Design: Features ice crystal elements embedded in the resin, creating a captivating and elegant appearance reminiscent of frozen landscapes.

- Color Customization: The epoxy resin color can be tailored to match your decor and personal taste.

- Smooth Finish: Expertly sanded and polished to achieve a mirror-like surface, enhancing the clarity and beauty of the embedded ice crystals.

- Durable Base: Includes a sturdy and stylish base, available in metal or wood, ensuring both aesthetic appeal and stability.

Specifications:

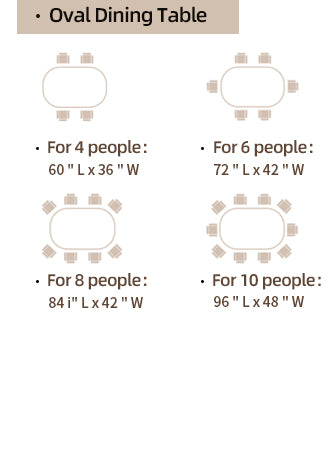

- Dimensions: Customizable based on client requirements.

- Materials: High-quality epoxy resin and premium woods (Black Walnut, Walnut, Poplar, Cunninghamia, Ash Wood, Olive Wood, etc.).

- Color: Clear epoxy resin with ice crystal elements, customizable to preferred colors.

- Table Base: Options for metal or wood bases.

Usage Scenarios:

Ideal for dining rooms, kitchens, or any dining area where you want to make a statement. This table not only provides a functional dining surface but also adds a touch of luxury and uniqueness to your home.

Customization Process:

- Design Consultation: Discuss your requirements and preferences with our design team.

- Material Selection: Choose your wood type, epoxy resin color, and embedded elements.

- Crafting: Our skilled artisans will meticulously craft each table according to your custom specifications.

- Showcase and Approval: We will present the finished product for your approval to ensure complete satisfaction.

- Packaging and Shipping: Professionally packaged to protect the table during transit, ensuring it arrives in perfect condition.

Elevate your dining experience with the Custom Epoxy Resin Live Edge Ice Crystal Dining Table CRT-036.

Showcase your sophisticated taste and transform your dining space with a table that combines natural beauty and modern elegance. Contact us today to customize your exclusive dining table!